Exploring Rapid Prototype Molding: Transforming Businesses with Advanced Metal Fabrication

The modern manufacturing landscape is rapidly evolving, and with it, the demand for rapid prototype molding is skyrocketing. This innovative approach to metal fabrication not only enhances productivity but also significantly reduces costs, making it a strategic advantage for businesses aiming to stay ahead in a competitive market. In this article, we'll delve deep into the nuances of rapid prototype molding, its benefits, and how it perfectly aligns with the needs of metal fabricators like Deepmould.net.

What is Rapid Prototype Molding?

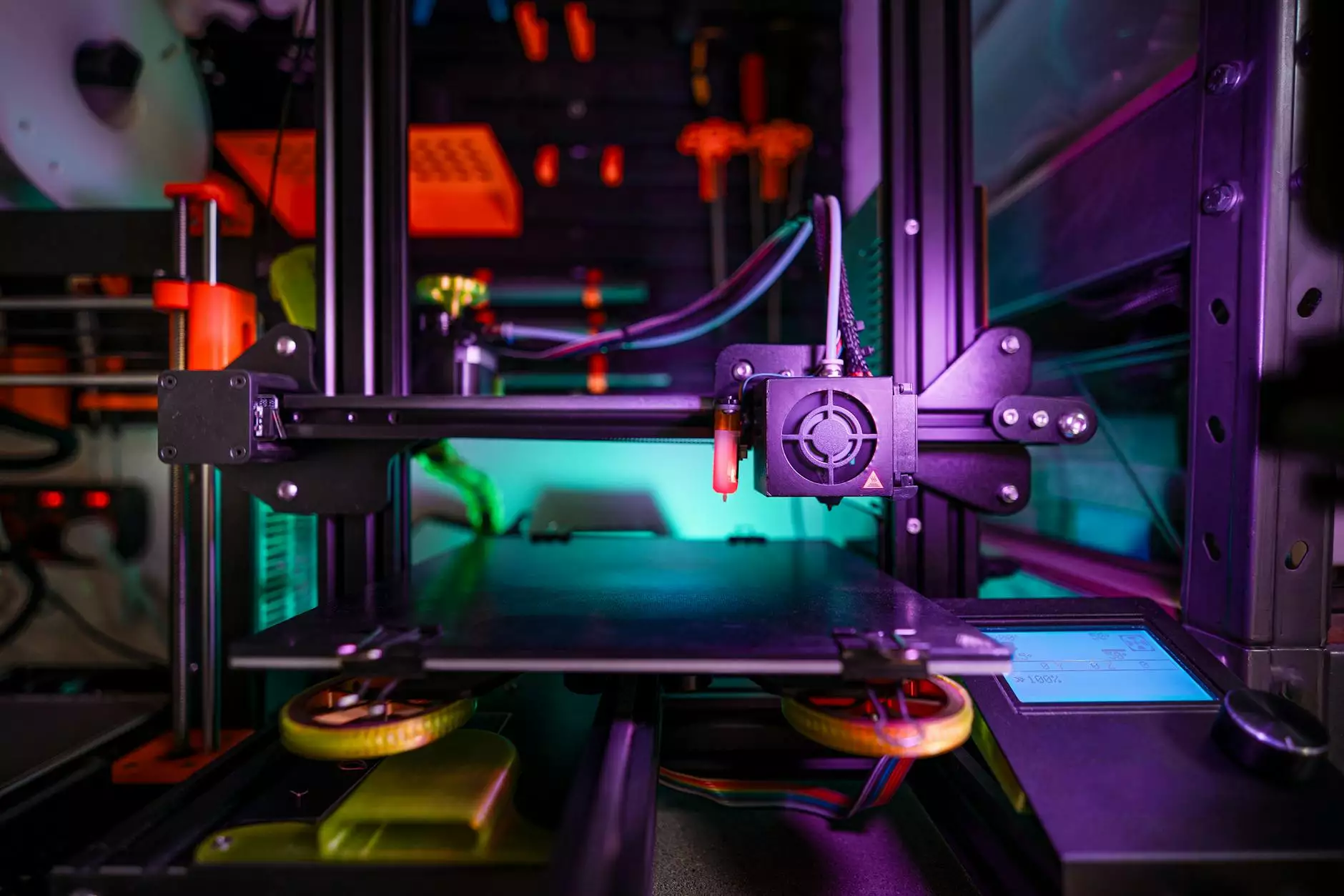

Rapid prototype molding is a process used to create physical models quickly through different methods such as 3D printing, CNC machining, or injection molding. Unlike traditional manufacturing processes that can take weeks or even months, this method offers a streamlined approach that allows engineers and designers to bring their concepts to life in mere days.

The Advantages of Rapid Prototype Molding

- Speed: The primary benefit of rapid prototype molding is the speed of production. Designers can test and iterate their designs without the long lead times associated with conventional methods.

- Cost-Effectiveness: It significantly reduces the costs involved in the prototyping phase, allowing companies to allocate resources more efficiently.

- Design Flexibility: Changes can be made on-the-fly, making it easier to adapt designs based on testing and feedback.

- Enhanced Collaboration: Rapid prototyping fosters better collaboration between teams, as tangible models can be shared and discussed in real-time.

- Lower Material Wastage: Advanced technologies used in rapid prototype molding result in minimal waste, adhering to sustainable practices.

Applications of Rapid Prototype Molding in Metal Fabrication

The applications of rapid prototype molding within the metal fabrication sector are vast. Here are several key areas where this technology can make a significant impact:

1. Product Development

In product development, rapid prototype molding allows for the swift creation of prototypes for new products. This encourages innovation and speeds up the time to market for new solutions. Companies can design, create, and test their products in a fraction of the time it would typically take.

2. Design Testing

Rapid prototyping is crucial for design testing. It enables engineers to validate form, fit, and function through real-world testing, ensuring that the final product meets customer expectations and industry standards.

3. Manufacturing Aids

Manufacturing aids such as jigs and fixtures can also be produced quickly. In metal fabrication, these tools improve efficiency and precision during manufacturing processes, ultimately improving product quality.

4. Customized Solutions

With rapid prototype molding, companies can create customized solutions tailored to specific client needs, enhancing customer satisfaction and creating a unique selling proposition.

Implementing Rapid Prototype Molding in Business Strategy

For metal fabricators, incorporating rapid prototype molding into the business strategy can lead to numerous advantages.

1. Streamlining Operations

By integrating this technology, businesses can streamline their operations. Faster prototyping translates to quicker production cycles, allowing companies to respond promptly to market demands.

2. Competitive Advantage

With the ability to turn ideas into products rapidly, companies that adopt rapid prototyping can maintain a competitive edge in the marketplace. Faster innovation leads to being first to market.

3. Risk Reduction

Prototyping early in the development process reduces the risk of costly errors later on. With tangible models, businesses can identify potential design flaws before full-scale production begins.

Case Studies: Success Stories of Rapid Prototype Molding

To better understand the impact of rapid prototype molding in the industry, here are a few success stories from businesses that have embraced this technology:

Case Study 1: Automotive Industry

An automotive manufacturer utilized rapid prototype molding to design and refine a new component for one of their vehicle lines. By creating multiple prototypes for testing, they were able to reduce the development time by 30%, leading to a timely product launch.

Case Study 2: Aerospace Sector

The aerospace industry, known for its stringent regulations and quality standards, has also benefitted. A company employed rapid prototyping to design lightweight components, allowing them to make adjustments based on real-world testing, thus achieving significant weight reductions while maintaining strength.

Case Study 3: Consumer Electronics

A consumer electronics firm that developed a new gadget used rapid prototype molding to create a series of working models. This approach allowed them to gather user feedback early in the design stage, leading to a more user-friendly final product.

The Future of Rapid Prototype Molding

The future of rapid prototype molding is bright, with continuous advancements in technology. As materials and methods evolve, so will the possibilities in terms of what can be created and how quickly.

1. Advanced Materials

Future developments in material science will enable the creation of prototypes using metals that have desirable properties such as higher durability and lighter weight. This will further enhance the capabilities of metal fabricators.

2. Digital Integration

The integration of AI and machine learning into the design and prototyping process will streamline workflows, predict outcomes, and enhance data-driven decision-making.

3. Sustainable Practices

As sustainability continues to be a priority in manufacturing, rapid prototype molding will contribute to greener practices by reducing waste and optimizing the use of materials.

Choosing the Right Partner: Why Deepmould.net Stands Out

When it comes to implementing rapid prototype molding successfully, choosing the right partner is crucial. Deepmould.net shines in several key areas:

1. Expertise

With years of experience in metal fabrication, Deepmould.net's team of specialists understands the intricacies of rapid prototype molding, ensuring high-quality results every time.

2. State-of-the-Art Technology

The latest technologies are employed to deliver precise and rapid prototypes, meeting the unique needs of various industries from automotive to healthcare.

3. Client-Centric Approach

Deepmould.net prioritizes client satisfaction by providing personalized solutions that cater to the specific requirements of each project, ensuring that clients get the best possible outcome.

4. Comprehensive Services

From initial design to final production, Deepmould.net offers a full spectrum of services that encompass all aspects of rapid prototype molding, thereby simplifying the process for clients.

Conclusion: The Transformative Power of Rapid Prototype Molding

In conclusion, rapid prototype molding is no longer just a trend; it is a transformative process that is reshaping the landscape of metal fabrication. Businesses that harness this technology stand to gain significant advantages, from reduced production times and costs to enhanced design flexibility and product innovation. By partnering with experts like Deepmould.net, companies can capitalize on the benefits of rapid prototype molding to drive their success in an ever-evolving market.

As the future unfolds, the integration of advanced technologies and sustainable practices in rapid prototyping will continue to push boundaries, making it an indispensable resource for forward-thinking businesses.